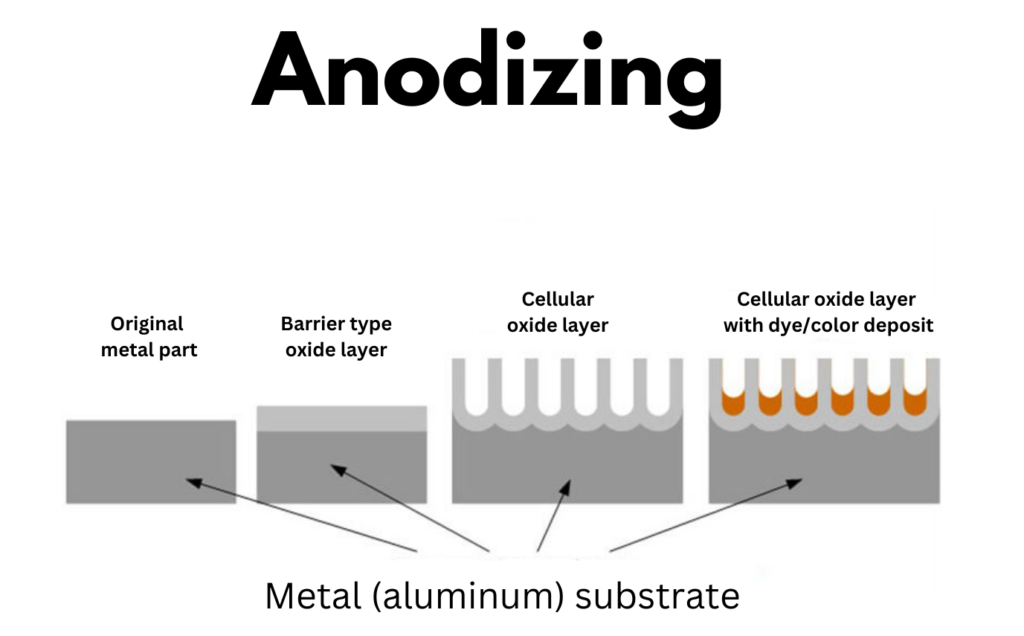

Hard Anodizing Layer Thickness . 8 rows sulphuric anodising or hard anodising is a better choice for improving wear qualities. Hard anodising provides the best resistance to both. Natural oxide layers are generally 2 to 3 nanometers thick—with type. Hard coat anodizing increases the thickness of the naturally occurring oxide layer on aluminum surfaces. Hard coat anodizing is the thickest of the three types of anodizing. The resulting hard anodic oxide layer protects aluminum. Hard coating anodizing, also known as hard anodization, is an electrochemical process used to thicken the natural oxide layer on the surface of aluminum. This type of anodizing process can form a very thick oxide. The aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes.

from www.valencesurfacetech.com

8 rows sulphuric anodising or hard anodising is a better choice for improving wear qualities. Hard anodising provides the best resistance to both. Hard coating anodizing, also known as hard anodization, is an electrochemical process used to thicken the natural oxide layer on the surface of aluminum. Natural oxide layers are generally 2 to 3 nanometers thick—with type. Hard coat anodizing increases the thickness of the naturally occurring oxide layer on aluminum surfaces. This type of anodizing process can form a very thick oxide. The resulting hard anodic oxide layer protects aluminum. The aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. Hard coat anodizing is the thickest of the three types of anodizing.

Anodizing Vs. Plating Key Differences And Similarities

Hard Anodizing Layer Thickness Hard coat anodizing increases the thickness of the naturally occurring oxide layer on aluminum surfaces. 8 rows sulphuric anodising or hard anodising is a better choice for improving wear qualities. Natural oxide layers are generally 2 to 3 nanometers thick—with type. This type of anodizing process can form a very thick oxide. Hard coat anodizing increases the thickness of the naturally occurring oxide layer on aluminum surfaces. Hard coat anodizing is the thickest of the three types of anodizing. The resulting hard anodic oxide layer protects aluminum. Hard anodising provides the best resistance to both. The aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. Hard coating anodizing, also known as hard anodization, is an electrochemical process used to thicken the natural oxide layer on the surface of aluminum.

From aerospacemetalsllc.com

The Very Versatile Hardcoat Anodize Process Aerospace Metals Hard Anodizing Layer Thickness Natural oxide layers are generally 2 to 3 nanometers thick—with type. The aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. Hard anodising provides the best resistance to both. 8 rows sulphuric anodising or hard anodising is a better choice for improving wear qualities. This type of anodizing process can form a. Hard Anodizing Layer Thickness.

From www.researchgate.net

Types of anodic aluminum oxide and corresponding currenttime Hard Anodizing Layer Thickness Hard coating anodizing, also known as hard anodization, is an electrochemical process used to thicken the natural oxide layer on the surface of aluminum. 8 rows sulphuric anodising or hard anodising is a better choice for improving wear qualities. Hard anodising provides the best resistance to both. Hard coat anodizing is the thickest of the three types of anodizing. The. Hard Anodizing Layer Thickness.

From www.intechopen.com

Aluminum Anodic Oxide AAO as a Template for Formation of Metal Hard Anodizing Layer Thickness Hard coating anodizing, also known as hard anodization, is an electrochemical process used to thicken the natural oxide layer on the surface of aluminum. Natural oxide layers are generally 2 to 3 nanometers thick—with type. The resulting hard anodic oxide layer protects aluminum. This type of anodizing process can form a very thick oxide. Hard coat anodizing increases the thickness. Hard Anodizing Layer Thickness.

From aluconsult.com

How to Anodize Aluminum Type II Anodizing for Beginners AluConsult Hard Anodizing Layer Thickness Hard coating anodizing, also known as hard anodization, is an electrochemical process used to thicken the natural oxide layer on the surface of aluminum. The resulting hard anodic oxide layer protects aluminum. Natural oxide layers are generally 2 to 3 nanometers thick—with type. 8 rows sulphuric anodising or hard anodising is a better choice for improving wear qualities. Hard coat. Hard Anodizing Layer Thickness.

From www.researchgate.net

(a) Pore size and (b) layer thickness as a function of anodizing time Hard Anodizing Layer Thickness Hard coat anodizing is the thickest of the three types of anodizing. The aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. This type of anodizing process can form a very thick oxide. The resulting hard anodic oxide layer protects aluminum. Natural oxide layers are generally 2 to 3 nanometers thick—with type.. Hard Anodizing Layer Thickness.

From www.mdpi.com

Coatings Free FullText A Review on Anodizing of Aerospace Aluminum Hard Anodizing Layer Thickness Hard coat anodizing increases the thickness of the naturally occurring oxide layer on aluminum surfaces. Hard anodising provides the best resistance to both. Hard coating anodizing, also known as hard anodization, is an electrochemical process used to thicken the natural oxide layer on the surface of aluminum. The resulting hard anodic oxide layer protects aluminum. The aluminum anodizing and hardcoating. Hard Anodizing Layer Thickness.

From www.valencesurfacetech.com

What Is The Purpose Of Anodizing? Valence Surface Technologies Hard Anodizing Layer Thickness Hard coating anodizing, also known as hard anodization, is an electrochemical process used to thicken the natural oxide layer on the surface of aluminum. The aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. Natural oxide layers are generally 2 to 3 nanometers thick—with type. Hard anodising provides the best resistance to. Hard Anodizing Layer Thickness.

From ebrary.net

Physical Properties of Anodic TiO2 Nanotube Layers Annealed at Hard Anodizing Layer Thickness Hard anodising provides the best resistance to both. Hard coat anodizing increases the thickness of the naturally occurring oxide layer on aluminum surfaces. 8 rows sulphuric anodising or hard anodising is a better choice for improving wear qualities. This type of anodizing process can form a very thick oxide. The aluminum anodizing and hardcoating processes are described with a design. Hard Anodizing Layer Thickness.

From www.mdpi.com

Coatings Free FullText The Sealing Step in Aluminum Anodizing A Hard Anodizing Layer Thickness 8 rows sulphuric anodising or hard anodising is a better choice for improving wear qualities. Hard coat anodizing is the thickest of the three types of anodizing. Hard anodising provides the best resistance to both. Natural oxide layers are generally 2 to 3 nanometers thick—with type. The aluminum anodizing and hardcoating processes are described with a design guide for coating. Hard Anodizing Layer Thickness.

From knowledge.electrochem.org

Electrochemistry Encyclopedia Anodizing Hard Anodizing Layer Thickness Natural oxide layers are generally 2 to 3 nanometers thick—with type. Hard anodising provides the best resistance to both. This type of anodizing process can form a very thick oxide. Hard coat anodizing is the thickest of the three types of anodizing. Hard coat anodizing increases the thickness of the naturally occurring oxide layer on aluminum surfaces. The resulting hard. Hard Anodizing Layer Thickness.

From www.aluminumanodizing.com

Hard Anodizing Companies Hard Anodizing Services Hard Anodizing Layer Thickness 8 rows sulphuric anodising or hard anodising is a better choice for improving wear qualities. The resulting hard anodic oxide layer protects aluminum. Hard coating anodizing, also known as hard anodization, is an electrochemical process used to thicken the natural oxide layer on the surface of aluminum. Natural oxide layers are generally 2 to 3 nanometers thick—with type. This type. Hard Anodizing Layer Thickness.

From fractory.com

Aluminium Anodising Process & Benefits Explained Fractory Hard Anodizing Layer Thickness The resulting hard anodic oxide layer protects aluminum. Hard anodising provides the best resistance to both. 8 rows sulphuric anodising or hard anodising is a better choice for improving wear qualities. Natural oxide layers are generally 2 to 3 nanometers thick—with type. This type of anodizing process can form a very thick oxide. Hard coat anodizing increases the thickness of. Hard Anodizing Layer Thickness.

From www.mdpi.com

Coatings Free FullText The Sealing Step in Aluminum Anodizing A Hard Anodizing Layer Thickness This type of anodizing process can form a very thick oxide. The resulting hard anodic oxide layer protects aluminum. Hard coating anodizing, also known as hard anodization, is an electrochemical process used to thicken the natural oxide layer on the surface of aluminum. Hard coat anodizing increases the thickness of the naturally occurring oxide layer on aluminum surfaces. The aluminum. Hard Anodizing Layer Thickness.

From www.valencesurfacetech.com

Anodizing Vs. Plating Key Differences And Similarities Hard Anodizing Layer Thickness 8 rows sulphuric anodising or hard anodising is a better choice for improving wear qualities. Hard coat anodizing is the thickest of the three types of anodizing. The aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. Hard anodising provides the best resistance to both. The resulting hard anodic oxide layer protects. Hard Anodizing Layer Thickness.

From www.researchgate.net

I'm doing anodization on Al 5052. How do I measure the thickness of the Hard Anodizing Layer Thickness The resulting hard anodic oxide layer protects aluminum. Natural oxide layers are generally 2 to 3 nanometers thick—with type. The aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. 8 rows sulphuric anodising or hard anodising is a better choice for improving wear qualities. Hard coat anodizing is the thickest of the. Hard Anodizing Layer Thickness.

From www.anoplate.com

Aluminum Anodizing Industrial Metal Finishing Anoplate, Inc. Hard Anodizing Layer Thickness 8 rows sulphuric anodising or hard anodising is a better choice for improving wear qualities. The aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. Hard coat anodizing increases the thickness of the naturally occurring oxide layer on aluminum surfaces. Hard anodising provides the best resistance to both. The resulting hard anodic. Hard Anodizing Layer Thickness.

From incertec.com

Type 3 Hardcoat Anodizing MILA8625 INCERTEC Hard Anodizing Layer Thickness Hard coating anodizing, also known as hard anodization, is an electrochemical process used to thicken the natural oxide layer on the surface of aluminum. 8 rows sulphuric anodising or hard anodising is a better choice for improving wear qualities. Hard coat anodizing increases the thickness of the naturally occurring oxide layer on aluminum surfaces. Natural oxide layers are generally 2. Hard Anodizing Layer Thickness.

From feeds2.feedburner.com

The natural formed oxide layer by clicking the link Hard Anodizing Layer Thickness This type of anodizing process can form a very thick oxide. Hard coat anodizing is the thickest of the three types of anodizing. Natural oxide layers are generally 2 to 3 nanometers thick—with type. Hard coating anodizing, also known as hard anodization, is an electrochemical process used to thicken the natural oxide layer on the surface of aluminum. 8 rows. Hard Anodizing Layer Thickness.